What you'll learn:

|

Reduced landing flaps, alslo called RFLA, refers to the practice of using flaps that are not fully deployed during the final approach until touchdown, provided that conditions and safety allow for it.

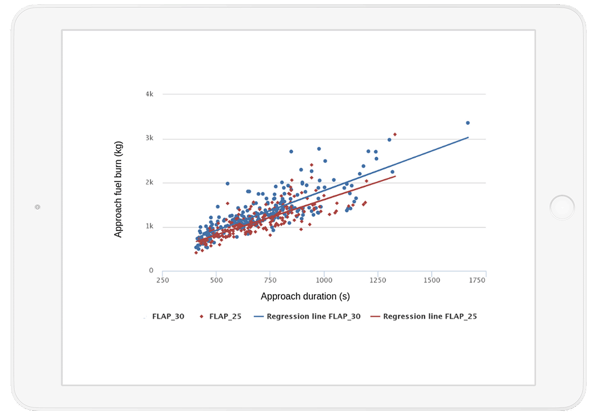

This means that the flaps are set at a reduced configuration instead of the usual full configuration. For example, on an A320 aircraft, the reduced flaps configuration is CONF 3 (20 degrees), while the full configuration is CONF FULL (35 or 40 degrees). On a B738 aircraft, the reduced flaps configuration is Flap 30 (30 degrees), while the full configuration is Flap 40 (40 degrees). See in the table below examples of landing flap configurations:

In blue, the reduced configuration and in red, the full one.

| Aircraft type ICAO code | Flaps configuration | FLAPS (°) |

| A320 | Conf Reduced | 20 |

| Conf Full | 35 or 40 | |

| B738 | Conf Reduced | 30 |

| Conf Full | 40 |

Most airplanes are certified to land with reduced landing flaps. Several aircraft types, such as the A330/340, are even certified for Autoland with reduced landing flaps.

Operational conditions apply, of course, and these will be integrated into the Standard Operating Procedures (SOPs). Reduced-flap landing will see an average 5 knots higher touch-down speed and an extra landing distance of around 500 feet (152.4m). Several airlines have made reduced flap landing procedures standard except for high-altitude airports, contaminated runways, or airports with short runways.

Among the extensive array of fuel efficiency best practices available, reduced flap landing stands out as one of the most frequently adopted techniques, and for good reason!

There are several benefits to selecting a reduced landing flaps configuration. Firstly, it reduces drag, which in turn requires less thrust and fuel consumption during the approach phase and therefore lowers CO2 emissions. Additionally, it helps to reduce noise disturbance near airports, which is particularly important in populated areas.

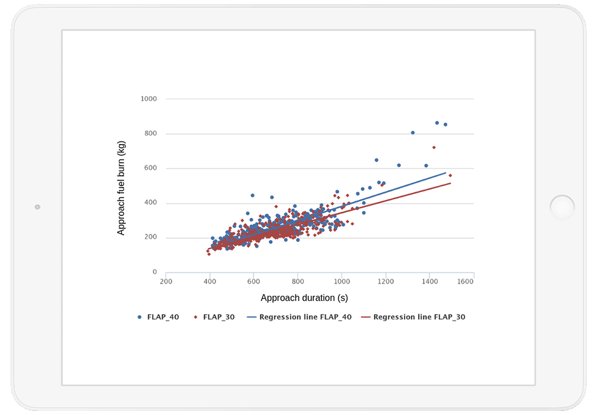

While the approach phase is not the most fuel-consuming phase of the flight, there are still significant fuel savings to be made by using a reduced landing flaps configuration.

For instance, a single-aisle aircraft such as the A320 or B737 can save between 7 to 10 kg of fuel per flight by applying this best practice. For larger aircraft, the benefits can exceed 25 kg per flight.

A320 Final approach fuel burn per flaps configuration (reduced or full). One point is one approach.

To put these savings into perspective, let's consider an airline operating a fleet of only 20 single-aisle aircraft, each flying 6 flights a day. Implementing a reduced landing flaps configuration that saves around 7 kg of fuel per flight would result in more than 300 tons of fuel saved per year, which is equivalent to over 100,000 gallons! These savings translate into significant cost reductions for the airline.

It is important to note that you play a vital role in implementing the reduced landing flaps best practice. By carefully calculating the landing performance, pilots ensure that the landing can be safely executed with the reduced flaps configuration. This is already a common practice at most international airports.

However, there are certain conditions that may prevent the application of reduced landing flaps, such as:

- High altitude airports

- Short runways

- Contaminated runways

- Tailwind that increases the approach speed

- High temperatures and low atmospheric pressures

- Need to vacate the runway quickly at the next taxiway

When conditions permit, here are a few tips to help you applicate reduced landing flaps without compromising safety:

- Ask your ground team to provide clear guidance and procedures on performing the practice and when it should be applied.

- Ask for training sessions to familiarize with the procedure.

- Focus on low-altitude airports and where the runway is long enough.

- Get the help of dedicated tools, such as a mobile app, that gives you personal and confidential feedback on each flight. This tool can also include best practices and 3D visualization, further enhancing your understanding and implementation of fuel-saving techniques.

You've completed the module!

Let's wrap it up!